Epoxy is really a form of resin which is created by mixing two factors alongside one another - a resin and a hardener. When both of these components are merged, a chemical reaction happens, resulting in a powerful, durable materials which might be utilized for several different programs. Epoxy is noted for its superb adhesion, chemical resistance, and mechanical Houses, making it a preferred option for a wide range of industries, like design, automotive, aerospace, and marine.

Epoxy is offered in many different types, like liquid, paste, and solid, and can be utilized as an adhesive, coating, or filler. It may be placed on a wide range of surfaces, together with metal, wood, concrete, and plastic, making it a versatile materials for a number of jobs. Epoxy is also accessible in an array of colours and finishes, which makes it very easy to personalize to suit the particular desires of the project.

Epoxy is frequently made use of together with other materials, such as fiberglass or carbon fiber, to make composite supplies which are lightweight and strong. It can also be used to be a protecting coating for surfaces that happen to be subjected to severe environments, such as chemical spills or extreme temperatures. In general, epoxy is a flexible and durable materials which has a wide range of apps throughout many alternative industries.

How Epoxy is Made use of

Epoxy is Utilized in an array of applications, from industrial to inventive. In the construction business, epoxy is usually utilised as an adhesive for bonding products jointly, including metallic to steel or metal to concrete. It is usually employed as a coating for flooring and partitions to supply security in opposition to chemicals, abrasion, and dampness. Within the automotive marketplace, epoxy is utilized for bonding overall body panels and repairing harmed components. It is additionally utilized for a protective coating for undercarriages and other metallic components to avoid corrosion.

During the marine sector, epoxy is useful for repairing fiberglass boats and developing customized components. It is additionally made use of as being a protective coating for hulls and decks to forestall h2o intrusion and harm from marine organisms. From the aerospace field, epoxy is used for bonding composite components collectively to build light-weight and powerful buildings. It is also utilized like a protective coating for aircraft elements to supply resistance from extreme temperatures and harsh environments.

Within the art globe, epoxy is used for making sculptures, jewelry, as well as other decorative items. It can be blended with pigments and various products to build exceptional types and finishes. Total, epoxy is a versatile content which might be used in a wide range of purposes, from industrial to creative.

Advantages of Utilizing Epoxy

There are numerous Advantages to using epoxy in several apps. One of many primary great things about epoxy is its exceptional adhesion Attributes. When adequately applied, epoxy sorts a powerful bond with the substrate, making a tough and extended-lasting relationship. This can make it an excellent option for programs where by sturdy adhesion is necessary, including in construction and automotive industries.

An additional benefit of working with epoxy is its chemical resistance. Epoxy is highly proof against a variety of chemical substances, which include acids, solvents, and oils. This makes it a great option for applications in which publicity to severe chemicals is frequent, for instance in industrial configurations or marine environments.

Epoxy also offers outstanding mechanical Houses, including substantial toughness and toughness. This makes it a perfect choice for programs the place toughness and effects resistance are very important, for instance inside the aerospace market or for generating personalized pieces in the maritime field.

Along with its Actual physical properties, epoxy also provides aesthetic Gains. It is available in a variety of hues and finishes, rendering it very easy to personalize to fit the precise requires of the task. This makes it a perfect option for apps the place visual appeal is very important, like in the art planet or for attractive coatings in residential or commercial options.

All round, epoxy offers a variety of Positive aspects that make it a super choice for many different apps across several industries.

Differing types of Epoxy

There are several differing types of epoxy accessible that you can buy, Every single with its own exclusive properties and apps. One widespread type of epoxy is called "epoxy resin," which can be a transparent liquid that can be combined with several additives to make custom made formulations. Epoxy resin is usually used for casting and encapsulating programs, for example generating attractive products or encapsulating electronic elements.

Guidelines for Dealing with Epoxy

Dealing with epoxy demands watchful awareness to element and proper approach to guarantee successful outcomes. A single critical suggestion for dealing with epoxy will be to thoroughly Adhere to the company's Guidance for mixing the resin and hardener. Good mixing is essential for attaining the specified properties in the epoxy and making sure a robust bond.

Basic safety Safeguards when Making use of Epoxy

Whilst epoxy provides many Added benefits for several applications, it is important to take good basic safety safeguards when working with this product. One particular crucial safety precaution when applying epoxy is to operate inside a well-ventilated place in order to avoid inhaling fumes in the resin and hardener. Epoxy fumes can be annoying towards the respiratory procedure and will cause dizziness or nausea if inhaled in significant concentrations.

Environmental Influence of Epoxy

Though epoxy gives many Positive aspects for numerous apps, it's important to consider its environmental affect. One likely environmental issue with epoxy is its manufacturing course of action, which can entail using chemicals which can be destructive towards the natural environment Otherwise correctly managed. It is crucial for manufacturers to get suitable steps to reduce the environmental effect of manufacturing epoxy by means of responsible sourcing of raw resources and squander administration techniques.

Jaleel White Then & Now!

Jaleel White Then & Now! Spencer Elden Then & Now!

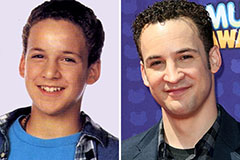

Spencer Elden Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now!